Contents

The thirst for new sources of energy is unquenchable, but we seldom realize that we are wasting a part of the electrical energy every day due to the lagging power factor in the inductive loads we use. Hence there is an urgent need to avoid this wastage of energy.

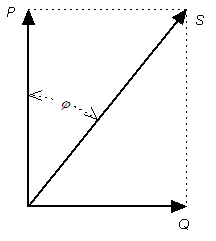

Before getting into the details of Power factor correction, lets just brush our knowledge about the term “power factor”. In simple words power factor basically states how far the energy provided has been utilized. The maximum value of power factor is unity. So closer the value of P.F to unity, better is the utility of energy or lesser is the wastage. In electrical terms Power factor is basically defined as the ratio of the active power to reactive power or it is the phase difference between voltage and current. Active power performs useful work while Reactive power does no useful work but is used for developing the magnetic field required by the device.

Most of the devices we use have power factor less than unity. Hence there is a requirement to bring this power factor close to unity. Here we are presenting a prototype for automatic power factor correction using PIC Microcontroller.

Circuit Diagram

Working

Comparator Section

The 230 V, 50 Hz is step downed using voltage transformer and current transformer is used to extract the waveforms of current. The output of the voltage transformer is proportional to the voltage across the load and output of current transformer is proportional to the current through the load. These waveforms are fed to Voltage Comparators constructed using LM358 op-amp. Since it is a zero crossing detector, its output changes during zero crossing of the current and voltage waveforms. These outputs are fed to the PIC which does the further power factor calculations.

Microcontroller Section

Correction Section

Power Factor Correcting capacitor connected parallel to load through relay, if the relay is energized by microcontroller it will connect the capacitor parallel with load, if relay deenergized it will remove the capacitor from the load. When the resistive load is on the power factor will be near to unity so the microcontroller doesn’t energize the relay coil. When the inductive load is on the power factor decrease now the microcontroller energize the relay coil in order to compensate the excessive reactive power. Hence according to the load the power factor is corrected.

MikroC Program

//LCD Module Connections

sbit LCD_RS at RB2_bit;

sbit LCD_EN at RB3_bit;

sbit LCD_D4 at RB4_bit;

sbit LCD_D5 at RB5_bit;

sbit LCD_D6 at RB6_bit;

sbit LCD_D7 at RB7_bit;

sbit LCD_RS_Direction at TRISB2_bit;

sbit LCD_EN_Direction at TRISB3_bit;

sbit LCD_D4_Direction at TRISB4_bit;

sbit LCD_D5_Direction at TRISB5_bit;

sbit LCD_D6_Direction at TRISB6_bit;

sbit LCD_D7_Direction at TRISB7_bit;

//End LCD Module Connections

int powerFactor()

{

int a=0,b=0,t=0,x=0;

float tm,pf;

TMR1L=0;

TMR1H=0;

do

{

if(PORTA.F0 == 1)

T1CON.F0 = 1;

else if(PORTA.F0 == 0 && T1CON.F0 == 1)

{

T1CON.F0 = 0;

break;

}

}while(1);

a = (TMR1L | (TMR1H<<8)) * 2;

TMR1L=0;

TMR1H=0;

do

{

if(PORTA.F0 == 1)

{

T1CON.F0=1;

if(PORTA.F1==1)

{

T1CON.F0=0;

break;

}

}

}while(1);

b = TMR1L | (TMR1H<<8);

tm = (float)b/a;

pf = cos(tm*2*3.14);

x=abs(ceil(pf*100));

return x;

}

void main()

{

char c[]="0.00";

int a,b,d,x,f,e;

float tm,pf;

Lcd_Init();

Lcd_Cmd(_LCD_CURSOR_OFF); // Cursor off

ADCON1 = 0x08; // To configure PORTA pins as digital

TRISA.F0 = 1; // Makes First pin of PORTA as input

TRISA.F1 = 1; //Makes Second pin of PORTA as input

TRISD.F0 = 0; //Makes Fist pin of PORTD as output

TRISD.F1 = 0; //Makes Second pin of PORTD as output

while(1)

{

a = powerFactor();

Delay_us(50);

b = powerFactor();

Delay_us(50);

d = powerFactor();

Delay_us(50);

e = powerFactor();

Delay_us(50);

f = powerFactor();

x = (a+b+d+f+e)/5;

c[3]=x%10 + 0x30;

x=x/10;

c[2]=x%10 + 0x30;

x=x/10;

c[0]=x%10 + 0x30;

Lcd_Out(1,1,"Power Factor");

Lcd_Out(2,1,c);

if(x<90)

{

PORTD.F0 = 1;

PORTD.F0 = 1;

Delay_ms(2000);

}

else

{

PORTD.F0 = 0;

PORTD.F0 = 0;

}

Delay_ms(250);

}

}

The function powerFactor() will find the current power factor by using the Timer 1 module of PIC 16F877a. Power Factor may be fluctuating, so to avoid it we will find power factor more than one time and its average is taken.

Note : This is only a prototype of Automatic Power Factor Controller, for practical implementation you may need to make some modifications in the program and circuit.